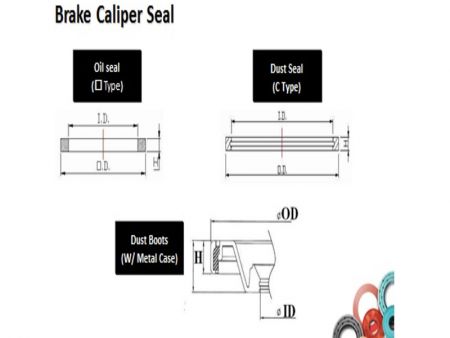

Brake Caliper Seal

Caliper Piston Seal & Dust Boot for Brake Systems

Brake Caliper Seals are divided into two types: piston seal and dust boot. One function of piston seal is to prevent brake fluid from leaking from the caliper. Another function is to pull the piston back to release the brake. The pressurized brake fluid forces the piston to slide out of the caliper.

The brake calipers have a dust-proof piston ring to protect the pistons and seals from road debris and water. Check these boots for wear when replacing the brake pads. The repair kit usually contains a new dust-proof piston ring and seal.

Product Material

Brake caliper seals are commonly made of EPDM rubber, which offers excellent resistance to brake fluids such as DOT3, DOT4, and DOT5. Based on your application requirements, we can provide professional recommendations to ensure the selected material meets both performance and durability expectations.

Our Advantages

1. NIYOK is the original parts supplier of Taiwan Honda, Nissan, Mitsubishi, Lotus, Luxgen and other well-known car manufacturers. If there is a need for customized gearbox oil seals, please leave relevant information such as CAD / CAM and other requirements. Based on this cooperation experience and project, we can provide you with advanced planning services and consulting for Brake Caliper Seal.

2. The Standard Product Inventory is Wide and Complete: NIYOK stocks the standard products and supplies the most common inch sizes. It can manufacture precise Brake Caliper Seal according to various industrial needs and deliver them quickly and on time, made of high-quality rubber, with good performance.

3. Low Mold Cost: Most of the various Brake Caliper Seal standard specifications already have molds, and no additional investment is required. If there is a special size that needs to be opened, we will also give back to the customer at low cost, or jointly develop the mold for cooperation.

4. Flexible MOQ and Instant Delivery: It can support small orders from customers, MOQ is smaller than the industry, and sample testing is provided. Instant delivery allows customers to apply production scheduling more flexibly.

5. Auto Assembly Machine for Oil Seal Spring was introduced, the oil seal is more precise and faster production when inserting the spring, so that the delivery time and quality are more stable.

6. Fully Automatic Inspection: In 2020, the automatic inspection was introduced to ensure the quality of oil seal, overcome the bottleneck of manual inspection, and produce more efficient and fast output.

The Function of Brake Caliper Seal

L6The piston seal prevents the brake fluid from leaking from the caliper; the piston is pulled back to release the brake.

The dust boot blocks the entry of external contaminants.

NIYOK Brake Caliper Seal Service Introduction

Located in Taiwan since 1983, NIYOK SEALING PARTS CO., LTD. is a Brake Caliper Seal supplier and manufacturer with more than 40 years of experence in the Seal Industry.

With more than 40 years experience, NIYOK is specialized in leading seal and oil seal manufacture. From oil seals, O-rings, to gaskets, and customized products, application industries include manufacturing, chemical processing, defense, water treatment and filtration, hydraulics, fluid power, heavy trucks, automobiles, aerospace, oil and gas, medical and For life sciences, food and beverages, a complete product line is available for customer needs and specifications.

NIYOK has been offering customers high-quality Brake Caliper Seal production service, both with advanced technology and 40 years of experience, NIYOK ensures each customer's demands are met.